Home » POTASSIUM HUMATE FLAKES

JINGFENGR® Potassium Humate Flakes is a high-grade water-soluble organic potassium fertilizer, featuring a flake-like form that differs from powder. It contains 60% natural humic acid, 8-10% potassium oxide, 70% organic matter and 50% organic carbon, with 100% water solubility and weakly alkaline pH (9-10).

The flake structure ensures low dust, easy manual operation and controllable dissolution, suitable for both small-scale manual application and large-scale farm use.

1. Product Customization

- Formula adjustment: Humic acid (50%-70%), potassium oxide (5%-17%), organic matter/organic carbon ratios adjustable; 100% water solubility maintained.

- Form adaptation: Powder (standard) or ultra-fine powder (200-400 mesh) for different application equipment.

- Quality alignment: Complies with domestic/international (EU, Southeast Asia) standards.

2. Packaging & Branding

- Custom specifications: 100g/500g (retail), 1kg/5kg/25kg/50kg (regular), 1-ton bag (bulk for farms).

- Brand options: Pure OEM (your brand only) or technical endorsement support.

3. Supply Chain Support

- Fast delivery: 7-15 days for standard orders; 20-30 days for customized orders.(Without CIQ time)

4. Value-added Services

- Technical support: Planting advice and application solutions for end-users.

- Compliance assistance: Product registration and certification support for target markets.

📑JINGFENG Humic acid CERES Organic Certificate(Confirmation for Materials Used in Organic Agriculture)

📑REACH (Green chemical innovation, permitted in the EU)

📑ISO Certificate 9001 / ISO14001 / ISO22000

📑Heavy Metal Test Report from ISO certified lab

CONTACT US TO GET OUR LATEST DOCS.

📑 MSDS (POTASSIUM HUMATE FLAKES Material Safety Data Sheet)

📑 TDS (POTASSIUM HUMATE FLAKES Technical Data Sheet)

CONTACT US TO GET OUR LATEST DOCS.

▶️Case 1:Cotton Planting (Xinjiang)

Problem: Soil salinization, potassium deficiency causing boll drop.

Method: Basal application 45 kg/ha + flush application 22.5 kg/ha at flowering stage.

Effect: Boll drop rate reduced by 50%, lint yield increased by 17%, fiber quality improved.

▶️Case 2:Apple Orchard (Shanxi)

Problem: Manual application of powder causes dust, uneven nutrient supply.

Method: Pre-dissolved flush application 30 kg/ha at fruit expansion stage.

Effect: No dust pollution, apple coloring uniformity up to 89%, sugar content increased by 1.0°Brix.

▶️Case 3:Tomato Greenhouse (Hebei)

Problem: Rapid nutrient leaching in greenhouse soil.

Method: Fertigation 18 kg/ha at seedling stage.

Effect: Slow nutrient release, seedling survival rate increased by 12%, yield up 20%.

💬Q1: How is it different from potassium humate powder?

A: Potassium Humate Flake form has low dust, slower controllable dissolution (sustained nutrients) and is easier for manual operation, while powder dissolves faster for automated drip irrigation.

💬Q2: Is it suitable for small-scale farmers?

A: Yes! No dust, easy to weigh and spread manually, no need for professional dissolution equipment, perfect for small plots.

💬Q3: Will slow dissolution affect nutrient absorption?

A: No. It dissolves moderately to achieve slow-release potassium supply, avoiding leaching and ensuring long-term nutrient availability.

💬Q4: Can it reduce chemical potassium fertilizer usage?

A: Yes. It enhances potassium absorption rate, reducing traditional potassium fertilizer usage by 20-25%.

💬Q5: Is potassium humate flakes suitable for saline-alkali soil in northern regions?

A: Absolutely. Organic matter and carbon regulate soil ions, alleviating salinization and improving crop adaptability.

💬Q6: Does it need pre-dissolution for application?

A: Flush/fertigation requires pre-dissolution; basal application can be spread directly (dissolves gradually with irrigation).

💬Q7: What’s the advantage for orchard manual application?

A: No dust inhalation risk, easy to spread evenly under trees, avoiding powder drift waste.

💬Q8: Will storage cause potassium humate flakes crushing into powder?

A: Avoid heavy pressure; the flake structure is stable under normal storage, ensuring original form.

💬Q9: Is it compliant with green planting standards?

A: Yes. Natural ingredients, 100% water-soluble, no chemical additives, meeting green food production requirements.

💬Q10: What’s the cost-effectiveness for cash crops?

A: High! Reduces fertilizer waste and labor cost (low dust, easy operation), increasing per hectare income by 4500-9000 RMB.

BENEFITS

- Controllable Dissolution & Low Dust: Flake form avoids dust pollution during application, dissolves moderately (slower than powder) for sustained nutrient supply.

- Stable Nutrient Supply: 8-10% potassium oxide combines with humic acid, realizing slow-release potassium supplementation without nutrient leaching.

- Soil Conditioning: Organic matter and carbon improve soil aggregation, alleviate salinization and enhance water retention.

- Quality & Stress Resistance: Strengthens crop stalks, improves drought/cold resistance, and boosts fruit coloring and commodity rate.

POTASSIUM HUMATE FLAKES TECHNICAL DETAILS

| Technical Index | Specification |

|---|---|

| Humic Acid Content (dry basis)*2/*3 | ≥ 60% |

| Potassium Oxide (K₂O) Content | ≥8-10% |

| Organic Matter Content*1 | ≥ 70% |

| Organic Carbon Content*4 | ≥ 50% |

| Water Solubility | 100% |

| Moisture Content | ≤ 15% |

| pH Value (1% aqueous solution) | 9.0-10.0 |

| Shelf Life | 36 months (under specified storage conditions) |

*2 ISO5073 Analysis method

*3 ISO19822 / HPTA / AAPFCO / IHSS Analysis method

*4 HJ615 Analysis method

RECOMMENDED APPLICATIONS

Crops

Vegetables

Fruit Trees

| Application Method | Application Timing | Dosage (per hectare) |

|---|---|---|

| Basal Application (Manual Spreading) | Before sowing/transplanting | 37.5-52.5 kg (mixed with soil) |

| Flush Application (Pre-dissolved) | Flowering/fruit expansion stage | 22.5-30 kg (diluted 400-600 times) |

| Fertigation (Slow Dissolution) | Seedling/jointing stage | 15-22.5 kg (dissolved in irrigation water) |

*Usage Notes

- Avoid mixing with acids (e.g., hydrochloric acid) to prevent precipitation.

- Dilute first before application, ensure uniform spraying/dripping.

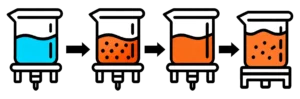

- Half-filled water

- Add liquid humic acid

- Add other fertilizers/pesticides

- Fill water and stir

POTASSIUM HUMATE FLAKES PACKAGING & STORAGE

1kg bag

5-25kg bag

Jumbo bag

We offer a range of standard packaging solutions: 1kg, 5kg, 10kg, 20kg bags, 25kg bags, jumbo bags.Custom packaging services are also available. Our team will provide tailored recommendations based on your specific requirements to ensure proper storage and transportation, maintaining product integrity throughout the process.

Storage Instructions

- Store in a cool, dry and well-ventilated warehouse (5-35℃, relative humidity ≤75%).

- Seal tightly after use to prevent moisture absorption and caking.

- Avoid direct sunlight and heavy pressure on flakes (prevent crushing into powder).

graeme@humate-cn.com

008618920222224

8618920222224

8618920222224