Home » Sodium-Free Potassium Humate

JINGFENGR® Sodium-Free Potassium Humate Flakes is a high-performance water-soluble organic potassium fertilizer engineered with a 100% sodium-free formula and elevated potassium oxide content (15%), setting it apart from standard potassium humate products.

Its uniform flake structure delivers low-dust handling, controllable dissolution. And hassle-free manual operation, making it a targeted solution for sodium-sensitive crops and high-end planting systems where soil sodium accumulation and nutrient efficiency are top priorities.

1. Product Customization

- Formula adjustment: Humic acid (50%-70%), potassium oxide (5%-17%), organic matter/organic carbon ratios adjustable; 100% water solubility maintained.

- Form adaptation: Powder (standard) or ultra-fine powder (200-400 mesh) for different application equipment.

- Quality alignment: Complies with domestic/international (EU, Southeast Asia) standards.

2. Packaging & Branding

- Custom specifications: 100g/500g (retail), 1kg/5kg/25kg/50kg (regular), 1-ton bag (bulk for farms).

- Brand options: Pure OEM (your brand only) or technical endorsement support.

3. Supply Chain Support

- Fast delivery: 7-15 days for standard orders; 20-30 days for customized orders.(Without CIQ time)

4. Value-added Services

- Technical support: Planting advice and application solutions for end-users.

- Compliance assistance: Product registration and certification support for target markets.

📑JINGFENG Humic acid CERES Organic Certificate(Confirmation for Materials Used in Organic Agriculture)

📑REACH (Green chemical innovation, permitted in the EU)

📑ISO Certificate 9001 / ISO14001 / ISO22000

📑Heavy Metal Test Report from ISO certified lab

CONTACT US TO GET OUR LATEST DOCS.

📑 MSDS (Sodium-Free Potassium Humate Material Safety Data Sheet)

📑 TDS (Sodium-Free Potassium Humate Technical Data Sheet)

CONTACT US TO GET OUR LATEST DOCS.

▶️Case 1: Citrus Planting (Sichuan, China)

Problem: Soil sodium accumulation (from conventional potassium fertilizers) caused leaf yellowing and fruit drop; potassium deficiency affected fruit sweetness.

Method: Basal application 50 kg/ha + flush application 35 kg/ha at fruit expansion stage.

Effect: Sodium content in soil decreased by 35%; leaf yellowing rate dropped by 60%; citrus sugar content increased by 1.2°Brix; yield improved by 22%.

▶️Case 2: Tobacco Planting (Yunnan, China)

Problem: Sodium-sensitive tobacco suffered from poor leaf quality due to sodium residues in common humate fertilizers.

Method: Fertigation 25 kg/ha at seedling stage and topping stage.

Effect: No sodium damage observed; tobacco leaf color became uniform; cured leaf grade rate increased by 25%; market price per kg rose by 0.3 USD.

▶️Case 3: Sugar Beet Planting (Inner Mongolia, China)

Problem: Saline-alkali soil with sodium accumulation inhibited beet root expansion and sugar accumulation.

Method: Basal application 60 kg/ha + topdressing 30 kg/ha at root expansion stage.

Effect: Soil sodium ion content reduced by 40%; beet root weight increased by 18%; sugar content improved by 1.0%.

💬Q1: How is this Sodium-Free product different from regular potassium humate flakes/powders?

💬Q2: Why is the sodium-free feature critical for crop planting?

💬Q3: Is it suitable for large-scale mechanized application?

💬Q4: Does the high K₂O content mean it can replace traditional potassium fertilizers?

💬Q5: How does its dissolution rate compare to potassium humate powder?

💬Q6: Is it compliant with international organic planting standards?

💬Q7: Can it be used in saline-alkali soil improvement?

💬Q8: What is the cost-effectiveness for cash crops like citrus and tobacco?

💬Q9: Will long-term storage affect its sodium-free feature?

💬Q10: Does it have any special advantages for greenhouse vegetable planting?

BENEFITS

- Sodium-Free & Sodium-Sensitive Crop Safe: No sodium residues, avoids soil sodium buildup and crop sodium damage, ideal for citrus, tobacco, grapes, and greenhouse vegetables.

- High-Efficiency Potassium Supply: 15% K₂O delivers concentrated potassium nutrition, satisfying peak demand during crop flowering and fruiting stages.

- Low Dust & Controllable Dissolution: Flake form reduces dust pollution during application; slower dissolution than powder ensures sustained nutrient release without leaching.

- Soil Conditioning & Quality Upgrade: Boosts soil aggregation, alleviates salinization, and enhances crop stress resistance and fruit commodity rate.

SODIUM-FREE POTASSIUM HUMATE TECHNICAL DETAILS

| Technical Index | Specification |

|---|---|

| Humic Acid Content (dry basis)*2/*3 | ≥ 60% |

| Potassium Oxide (K₂O) Content | ≥15% |

| Sodium Content | <1% |

| Organic Matter Content*1 | ≥ 70% |

| Organic Carbon Content*4 | ≥ 50% |

| Water Solubility | 100% |

| Moisture Content | ≤ 15% |

| pH Value (1% aqueous solution) | 9.0-10.0 |

| Shelf Life | 36 months (under specified storage conditions) |

*2 ISO5073 Analysis method

*3 ISO19822 / HPTA / AAPFCO / IHSS Analysis method

*4 HJ615 Analysis method

RECOMMENDED APPLICATIONS

Crops

Vegetables

Fruit Trees

| Application Method | Application Timing | Dosage (per hectare) |

|---|---|---|

| Basal Application (Manual Spreading) | Before sowing/transplanting | 45-60 kg (mixed with soil) |

| Flush Application (Pre-dissolved) | Flowering/fruit expansion stage | 30-45 kg (diluted 400-600 times) |

| Fertigation (Slow Dissolution) | Seedling/jointing stage | 22.5-30 kg (dissolved in irrigation water) |

*Usage Notes

- Avoid mixing with acids (e.g., hydrochloric acid) to prevent precipitation.

- Dilute first before application, ensure uniform spraying/dripping.

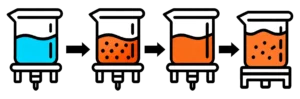

- Half-filled water

- Add liquid humic acid

- Add other fertilizers/pesticides

- Fill water and stir

SODIUM-FREE POTASSIUM HUMATE PACKAGING & STORAGE

1kg bag

5-25kg bag

Jumbo bag

We offer a range of standard packaging solutions: 1kg, 5kg, 10kg, 20kg bags, 25kg bags, jumbo bags.Custom packaging services are also available. Our team will provide tailored recommendations based on your specific requirements to ensure proper storage and transportation, maintaining product integrity throughout the process.

Storage Instructions

- Store in a cool, dry and well-ventilated warehouse (5-35℃, relative humidity ≤75%).

- Seal tightly after use to prevent moisture absorption and caking.

- Avoid direct sunlight and heavy pressure on flakes (prevent crushing into powder).

graeme@humate-cn.com

008618920222224

8618920222224

8618920222224