In recent years, mineral humic acid products have received attention and widespread application in agriculture, animal husbandry, industry and other fields due to their unique and obvious advantages, and they have also greatly promoted the development of these industries. In the previous article“Humic acid what is it and the formation process of humic acid.”, the author explained what mineral humic acid is and its formation process. Today the author will solve a more common problem for you——How to judge the quality of humic acid products?

Judging the quality of humic acid products is mainly from the following aspects:

Main reference items for judging the quality of humic acid products

1、Types of raw material sources: The raw materials are generally peat, lignite, and leonardite. Because peat is protected by the state and it is difficult to extract humic acid, lignite becomes one of the main raw materials for the production of humic acid. Leonardite can be also used as the raw material for extracting humic acid. The quality of humic acid extracted from high-quality leonardite is still acceptable.

2、Production process: Mineral humic acid is originally a weakly acidic organic substance. During production, strong alkalis such as potassium hydroxide, sodium hydroxide or ammonia are usually used to react with humic acid, form flakes, granules, crystals, and powders through various processing techniques.The pros and cons of the quality of mineral humic acid has no deep connection with appearance.

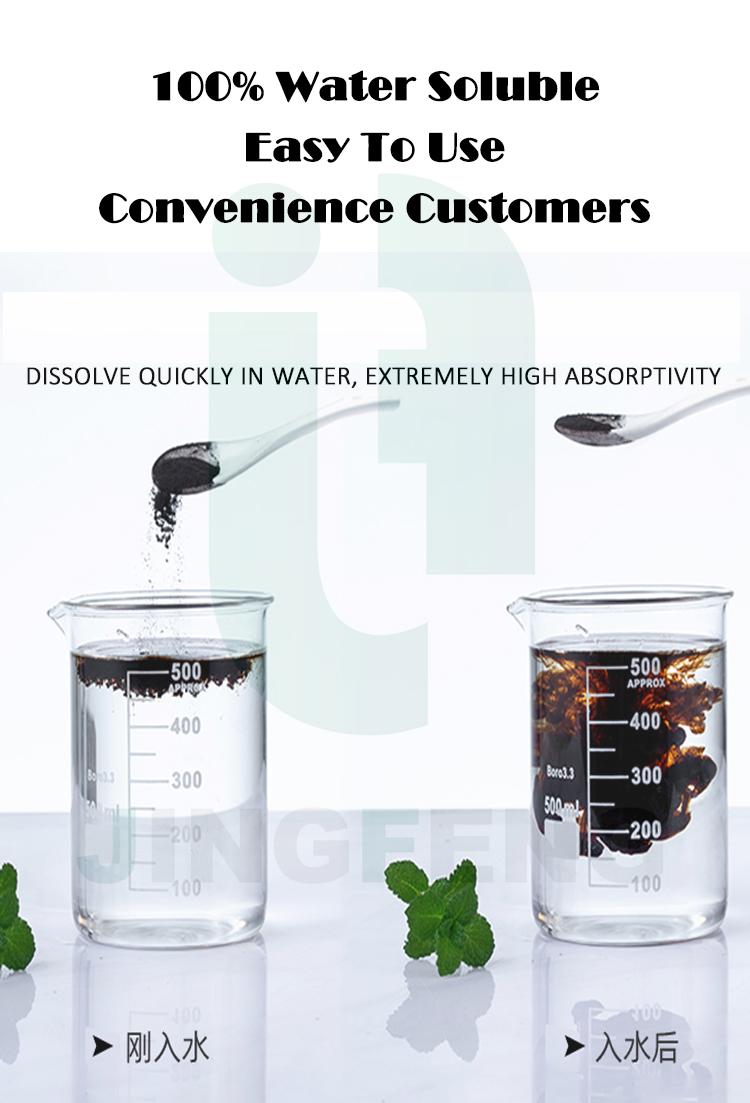

3、 Product solubility or anti-flocculation: The solubility depends on the insoluble matter of the product. The anti-flocculation depends on the degree of delamination when placed in water, but mainly depends on the the degree of sulfonation. Now in China, as the different national standard of fulvic acid test, most of miner fulvic acid or potassium fulvate just contains few fulvic acid. Its real name should be sulfonated potassium humate.

4、 Test the type of product ingredients and molecular weight: test the ratio of black humic acid, palm humic acid, and fulvic acid, No one ingredient is 100%.

5、Product activity level: check the ability of coordinating cations. Generally we use CaCl2 (calcium chloride) solution.

6、 Stability of compounding: not only mixing with N, P, K, but also solidifying ability to microorganisms and heavy metals in soil.

The above is the content shared with you in this article. I hope to help you. If any questions, please consult:

EU CERES certified humic acid manufacturer: graeme@humate-cn.com