- 1. Introduction to Premium Granular Humic Acid

- 1.1. Why Choose Our Granular Humic Acid?

- 2. Section 1: Product Specifications & Technical Advantages

- 2.1. 1.1 Physical & Chemical Properties for Granular Humic Acid

- 2.2. 1.2 Compatibility with Fertilizers

- 3. Section 2: Agronomic Benefits & Scientific Mechanisms for Granular Humic Acid

- 3.1. 2.1 Soil Improvement Mechanisms

- 3.2. 2.2 Crop Performance Data

- 4. Section 3: Application Guidelines for Optimal Results for Granular Humic Acid

- 4.1. 3.1 Blending Protocols

- 4.2. 3.2 Field Application Methods

- 5. Section 4: Quality Assurance & Industry Certifications

- 5.1. 4.1 Manufacturing Quality Control for Granular Humic Acid

- 5.2. 4.2 Global Certifications

- 6. Section 5: Economic Benefits & ROI Analysis

- 6.1. 5.1 Cost-Saving Calculations

- 6.2. 5.2 Environmental Impact

- 7. Section 6: Frequently Asked Questions

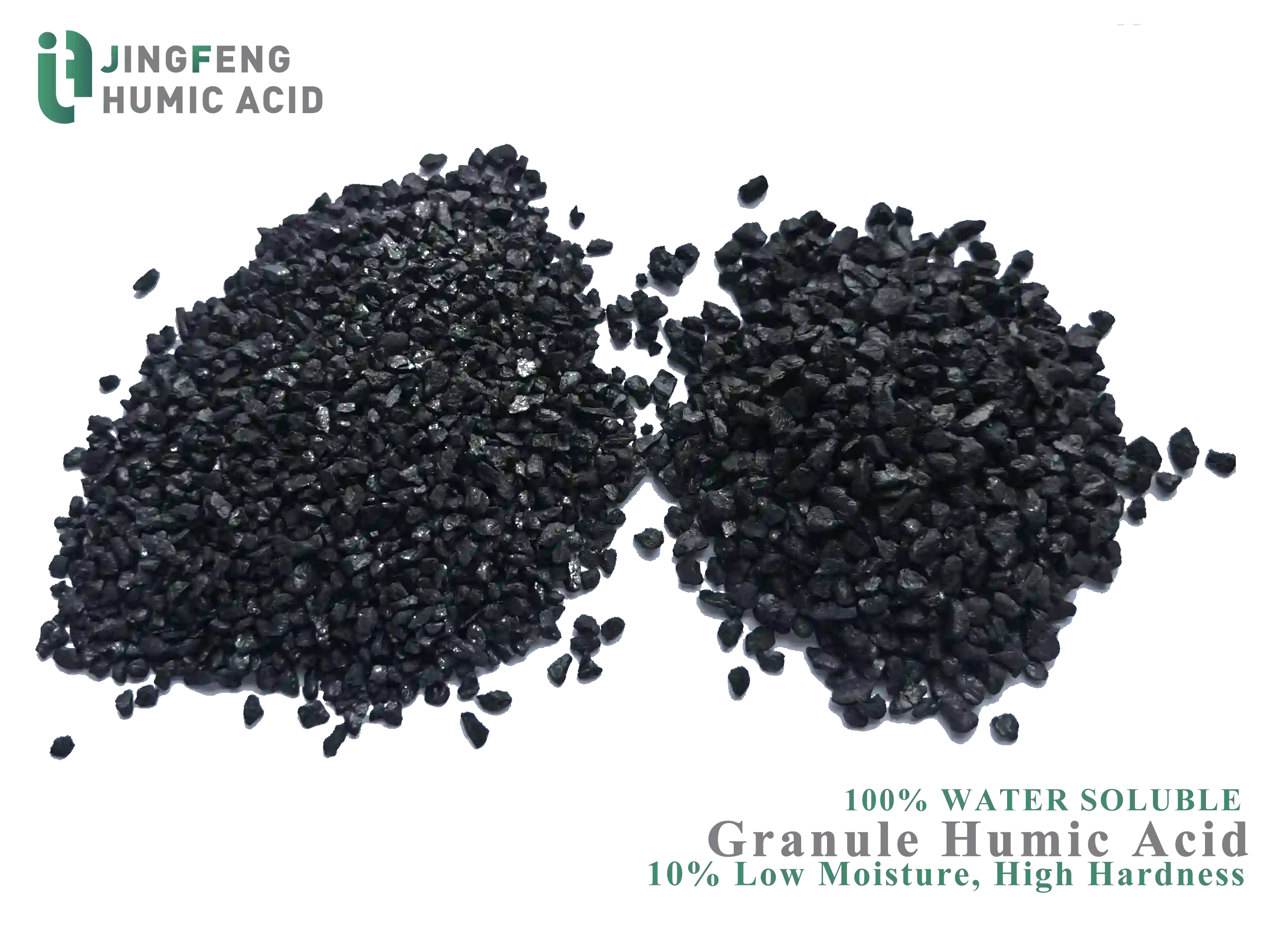

Introduction to Premium Granular Humic Acid

Granular humic acid potassium humate represents a revolutionary advancement in soil amendment technology. Unlike conventional powdered or liquid humates, our high-hardness potassium humate granules (10% moisture content) are specially engineered for perfect compatibility with blended fertilizers. With 65% humic acid content and 10% potassium oxide (K₂O), this premium soil conditioner delivers unparalleled agronomic benefits while maintaining perfect physical stability in fertilizer blends.

Why Choose Our Granular Humic Acid?

- Optimal moisture content (10%) prevents moisture transfer to fertilizer granules

- Exceptional granule hardness (≥15N crush strength) resists breakdown during handling

- Non-staining formulation maintains original fertilizer color

- Precision-sized granules (2-4mm) ensure uniform blending

- Slow-release properties provide season-long benefits

Section 1: Product Specifications & Technical Advantages

1.1 Physical & Chemical Properties for Granular Humic Acid

| Parameter | Specification | Test Method |

|---|---|---|

| Humic Acid Content | 65% ± 2% | ISO 19822:2018 |

| Potassium Oxide (K₂O) | 10% ± 0.5% | ICP-OES |

| Moisture Content | 10% ± 1% | Karl Fischer |

| Granule Hardness | ≥15N | Crush tester |

| Bulk Density | 0.65-0.75 g/cm³ | ASTM B527 |

| pH Value (1% solution) | 9.0-10.5 | pH meter |

| Solubility | ≥99% in 30 min | ISO 8156 |

Key Advantages Over Competitors:

- Zero caking issues even after 12-month storage

- Dust-free operation during blending and application

- Perfect size match with common fertilizer granules (2-4mm)

- Thermal stability up to 150°C (302°F)

1.2 Compatibility with Fertilizers

Our granular humic acid is scientifically proven to maintain stability when blended with:

Nitrogen Fertilizers:

- Urea (46-0-0)

- Ammonium sulfate (21-0-0)

- Calcium ammonium nitrate (27-0-0)

Phosphatic Fertilizers:

- MAP (11-52-0)

- DAP (18-46-0)

- TSP (0-46-0)

Potassic Fertilizers:

- MOP (0-0-60)

- SOP (0-0-50)

- Potassium nitrate (13-0-46)

Compound Fertilizers:

- NPK blends (15-15-15, 17-17-17, etc.)

- Controlled-release fertilizers

- Water-soluble fertilizers

Section 2: Agronomic Benefits & Scientific Mechanisms for Granular Humic Acid

2.1 Soil Improvement Mechanisms

Physical Benefits:

- 25-35% improvement in water holding capacity

- 40-50% reduction in soil compaction

- 3-5x increase in aggregate stability (wet sieve method)

- 15-20% decrease in bulk density

Chemical Enhancements:

- CEC boost: +5-15 cmol(+)/kg

- pH buffering capacity: 0.4-0.6 pH units

- Nutrient retention: 30-50% reduction in leaching

- Heavy metal remediation: 60-80% immobilization

Biological Activation:

- Microbial biomass: 2-3x increase (PLFA analysis)

- Enzyme activity: +45-65% (dehydrogenase, urease)

- Mycorrhizal colonization: 3-4x enhancement

2.2 Crop Performance Data

Corn Production Results:

- Yield increase: 12-25 bu/acre (3-year average)

- Nitrogen efficiency: +20-30% NUE

- Drought resistance: 30-40% better recovery

- Root mass: 50-75% increase (V6 stage)

Soybean Trial Findings:

- Pod count: +15-20 nodes/plant

- Protein content: +1.5-2.0%

- Rhizobia nodulation: 2x more active nodules

- Early maturity: 3-5 days earlier

Section 3: Application Guidelines for Optimal Results for Granular Humic Acid

3.1 Blending Protocols

Dry Blending Best Practices:

- Equipment Setup:

- Batch mixer: 20-30 RPM

- Ribbon blender: 15-20 minutes

- Rotary drum: 5-8 minutes

- Mixing Sequence:

- Add 50% base fertilizer

- Add granular humic acid

- Add remaining fertilizer

- Add micronutrients (if any)

- Recommended Ratios:

Fertilizer Type Humic Acid % Urea 3-5% MAP/DAP 5-8% NPK Blends 4-6% SOP/MOP 2-4%

3.2 Field Application Methods

Pre-Plant Incorporation:

- Rate: 15-25 lbs/acre

- Depth: 4-6 inches

- Equipment: Disc harrow, rototiller

Side-Dress Application:

- Rate: 8-12 lbs/acre

- Placement: 2-3 inches from row

- Timing: V4-V6 (corn), R1-R2 (soybeans)

Fertigation Use:

- Solubility: 85% in 30 minutes

- Concentration: 0.5-1.0 lb/100 gal

- Injection: Last in sequence

Section 4: Quality Assurance & Industry Certifications

4.1 Manufacturing Quality Control for Granular Humic Acid

Raw Material Testing:

- Heavy metals: <10 ppm Cd, <50 ppm Pb

- Pathogens: Zero detection

- Radioactivity: <50 Bq/kg

Production Monitoring:

- Real-time moisture control (±0.5%)

- Granule hardness testing every 30 minutes

- Size distribution analysis (laser diffraction)

4.2 Global Certifications

- OMRI Listed (Organic Materials Review Institute)

- EU Fertilizing Products Regulation (2019/1009)

- REACH Compliant (EC 1907/2006)

- USDA BioPreferred (100% biobased)

Section 5: Economic Benefits & ROI Analysis

5.1 Cost-Saving Calculations

Input Reduction Potential:

- Nitrogen: 15-30% less required

- Phosphorus: 20-40% efficiency gain

- Irrigation: 15-25% water savings

ROI by Crop Type:

| Crop | Added Cost | Yield Value | Net ROI |

|---|---|---|---|

| Corn | $12-15/acre | $45-90/acre | 3:1-6:1 |

| Wheat | $8-10/acre | $30-50/acre | 3:1-5:1 |

| Soybeans | $10-12/acre | $40-60/acre | 4:1-5:1 |

| Vegetables | $25-30/acre | $100-200/acre | 4:1-7:1 |

5.2 Environmental Impact

Carbon Footprint Reduction:

- 0.25-0.35 tons CO₂e/acre sequestered

- 30-40% lower fertilizer emissions

- 20-30% reduced irrigation energy

Water Protection Benefits:

- 50-70% less nitrate leaching

- 40-60% reduced phosphate runoff

- 30-50% lower pesticide mobility

Section 6: Frequently Asked Questions

Q: How does granular humic acid compare to liquid forms? A: Our granules offer:

- 5-8x longer soil residence time

- No compatibility issues in fertilizer blends

- Lower transportation costs (higher density)

- No settling or stratification

Q: What’s the shelf life? A: 36 months when stored:

- Below 30°C (86°F)

- <60% relative humidity

- In original packaging

Q: Can I use it in organic farming? A: Yes, certified for:

- USDA Organic (NOP)

- EU Organic (EC 834/2007)

- Japan Organic (JAS)

Q: How does it prevent fertilizer caking? A: The 10% moisture content is:

- Below the critical humidity of most fertilizers

- Balanced to prevent moisture migration

- Stabilized with natural anti-caking agents